The Control Panel Specialists

Manufacturers of quality bespoke control panels all in-house at our 17,000 square foot premises.

Design

First comes the design. When an order is placed our engineers get to work designing the parts. We use both 2D and 3D CAD to create accurate part drawings.

Program

Once design is complete and the customer is happy, we program the parts onto our CNC Punch for fast and accurate parts.

Forming

The parts are then sent through to the CNC press brake for press-forming ready for fabrication.

Fabrication

Once formed, its the turn of the fabricators. All parts will be fully welded and prepared for powder coating in one of our 5 large welding bays.

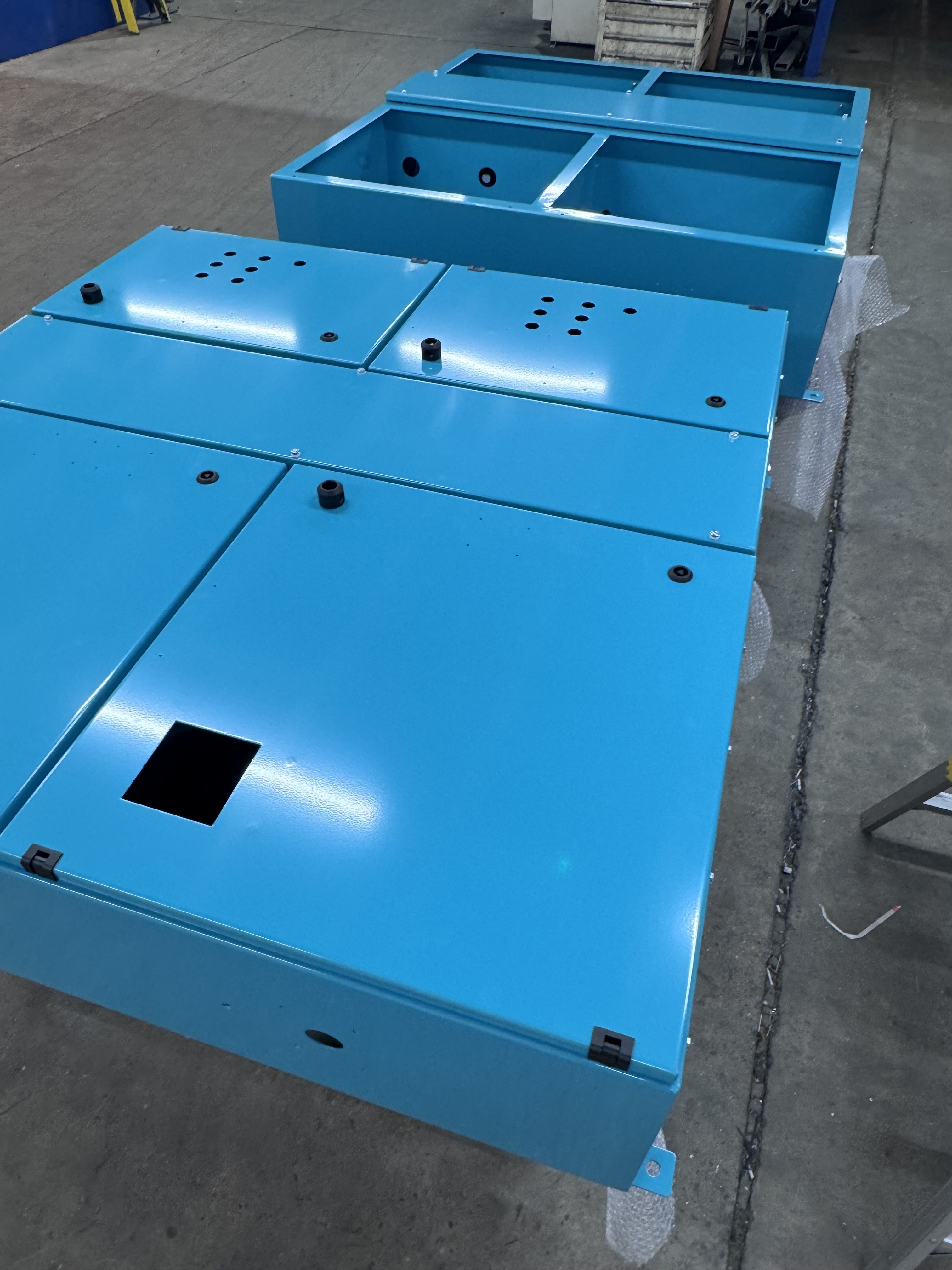

Powder Coating

All fabricated parts will be degreased ready for the powder coaters to apply the powder. We have 2 large spray booths. When ready the parts are loaded into our 4m deep oven and baked.

Assembly

The final stage is assembly. This is where all the parts come together to create the project that you require. Our assembly team will then QA the job and package it up ready for delivery to you…the customer.

Control Panels

Bespoke Fabrication

Although we specialise in control panels we also offer a much wider range of services. If its made from steel we can help you. See below a few of the projects we have undertaken. We also offer a powder coating service for already made parts. Get in touch

Our standard MSK1 kiosks being powder coated RAL 6005 Moss Green.

Powder Coating

All of our powder coating is done ‘In-House’ to allow us to keep full control of quality finishes to our products. With an internal dimension of 4m deep x 2.2m wide and 2.4m high, we can powder coat large enclosures and also any bespoke powder coating requirements